Gas heat exchangers

Before fuel gases can be used in CHP plant engines and converted into energy, they have to be cleaned and processed. This protects the engine and plant components and increases the service life significantly.

For these processes, we supply gas heat exchangers which cool the gas and precipitate condensate and additional heat exchangers which re-heat the gas for downstream processes in order to adjust the relative humidity.

Our gas heat exchangers can be used for a wide range of fuel gases.

Designs

Since our gas heat exchangers are designed and constructed on a project-specific basis, almost every one looks different and is suitable for a different application.

The most common designs are shown below.

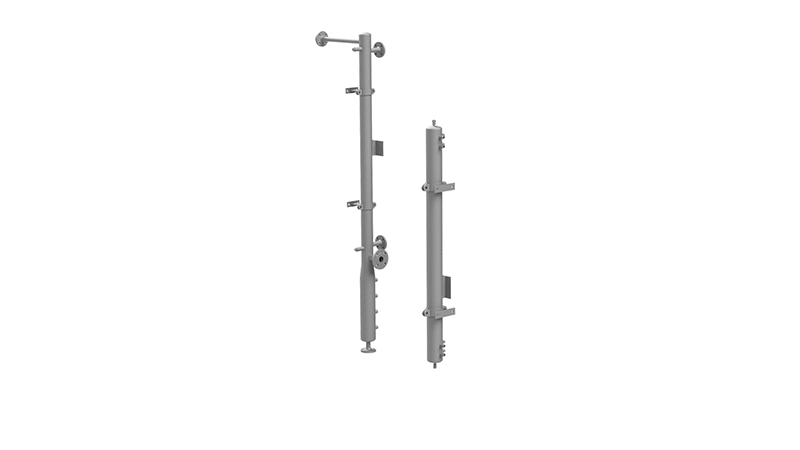

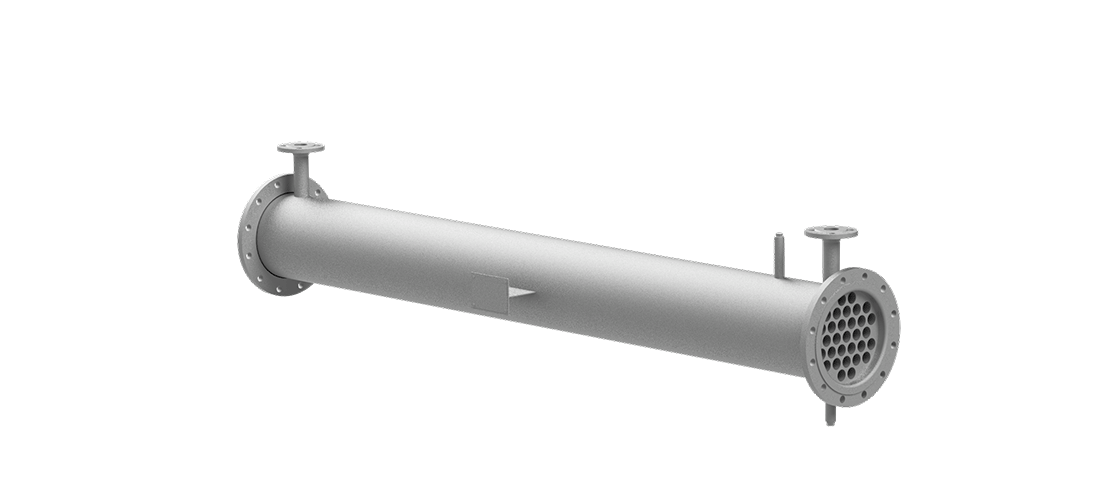

Tube bundle

This is the simplest version of our gas heat exchanger. In this case only the tube bundle with connection flanges is supplied for installation in the pipe. Precipitating condensate must be drained separately in a different location. Gas heaters are typically shipped as tube bundles.

This design can be installed in the plant both horizontally and vertically.

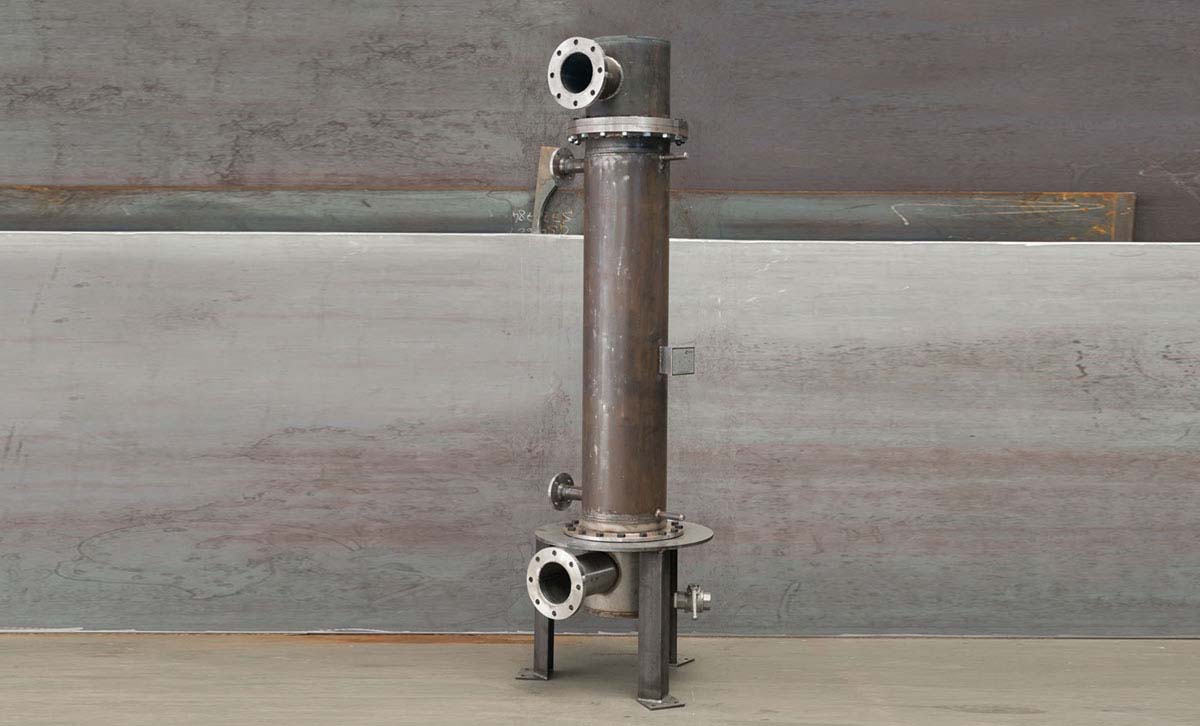

Chambers

This version contains an outlet chamber with integrated demister and, if applicable, also an additional inlet chamber. The demister prevents precipitating condensate from being carried along into the downstream pipe. The condensate collects in the demister instead, drips down and can be removed via a condensate drain.

Upon request by the customer, a factory-installed siphon acting as a water and gas seal can also be integrated into the gas cooler condensate connection.

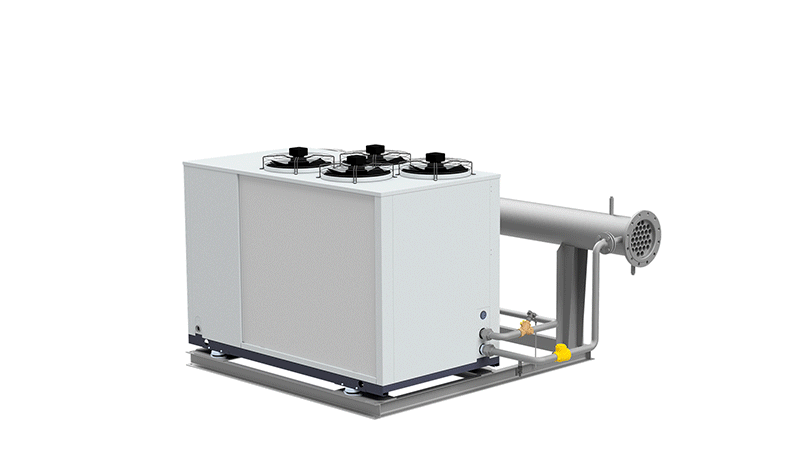

Gas cooling unit

In a gas cooling unit, the heat exchanger is equipped at the factory with a water chiller and mounted on a base frame and shipped as a closed, ready-to-connect system.

The system can be expanded with various options upon request, for example with a siphon or condensate collection container with electric trace heating. An additional heat exchanger can be installed directly at the gas cooler outlet for re-heating purposes.