More heat exchangers

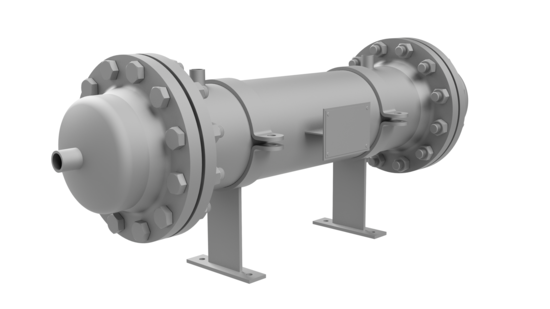

In addition to the focus on utilization of waste heat from combustion engines and gas turbines in combined heat and power plants (CHP plants) as well as gas processing in biogas, sewage gas and other plants, our tube bundle heat exchangers are also used in many other energy, environmental, industrial and process technology applications.

Some of the projects in these fields which lie outside our core business are described below.

Do you have an application where heat needs to be utilized and efficiency increased?

Then come talk to us, we will review whether we can offer you a suitable solution with our products.

ORC plants

The ORC cycle is a thermodynamic process similar to the well-known water-steam cycle used in conventional power plants to generate electricity. The main difference is that the ORC cycle uses an organic liquid with a low boiling point. That is why ORC systems work at lower temperatures compared to conventional water-steam cycles.

© Dürr

The Energy Tower

Heat exchangers for condensing systems in biogas plants

- Ready to connect in frame with chimney

- Eligible for subsidies through KFW / BAFA (as of 06/2021)

- Up to 80% higher thermal output

The use of condensing systems in biogas plants is normally not possible due to the damaging substances found in biogas, since sulphuric acid causes corrosion in the heat exchanger. However, we have developed a design which prevents this problem.

A combination of tube bundle heat exchanger with integrated graphite component, ready to connect in a frame with chimney.

This allows the thermal output of the CHP plant to be increased by up to 80%!

Example

CHP 430 kW el., exhaust gas mass flow: 2320 kg/h (wet)

Tube bundle-heat exchanger:

| exhaust gas in | 500 °C |

| exhaust gas out | 230 °C |

| pressure drop | 6 mbar |

| water in | 75 °C |

| water out | 98 °C |

| power | 197 kW |

Graphite-heat exchanger:

| exhaust gas in | 230 °C |

| exhaust gas out | 53 °C |

| pressure drop | 5,5 mbar |

| water in | 40 °C |

| water our | 46,1 °C |

| power | 141 kW |